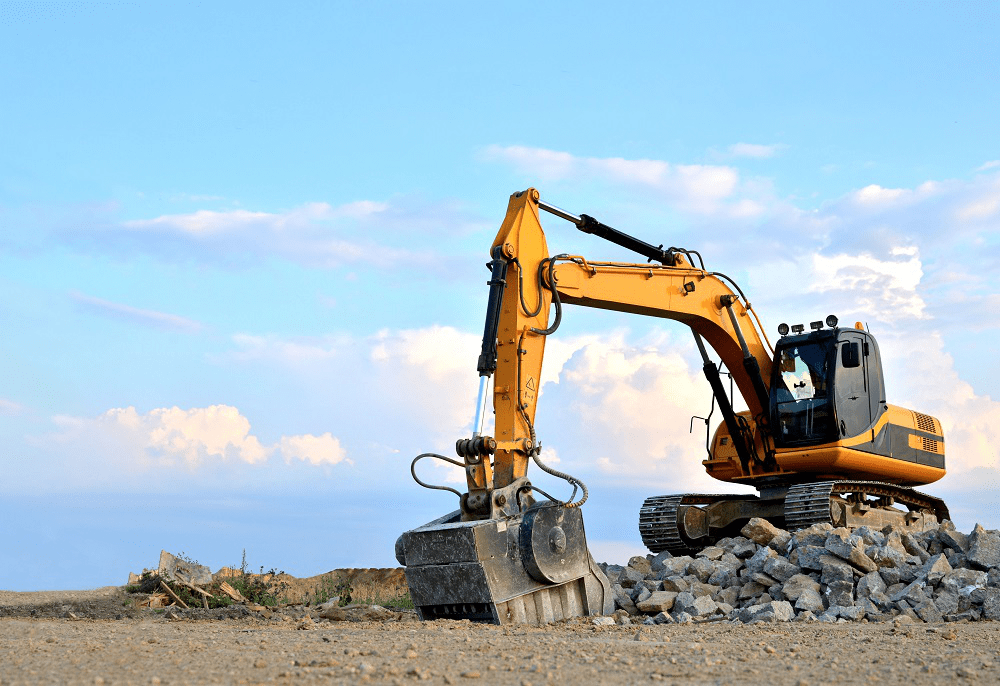

Concrete recycling happens by removing the concrete structure and then breaking and crushing the material into a specific size and quality. Concrete goes to a recycling site for crushing. Or a portable crushing rig can crush concrete on site.

Crushing Concrete to Specifications

Technology and equipment advances have allowed for a more comprehensive crushing of a much larger range of concretes. Once the material is crushed to specifications, the recycled concrete is used for construction projects in Baltimore and other Maryland areas.

Uses for Recycled Concrete

Typically, recycled concrete forms the subbase in road projects but can replace new concrete as an aggregate in construction projects. As a rule, any construction completed with recycled aggregates will bear no difference than construction prepared with rock or gravel aggregates.

Crushed aggregates can replace fresh gravel and rock for many projects such as parking lots, sound barriers, and sports fields. Crushed concrete can also serve as riprap erosion control. Using this recycled concrete will save money and help the environment. We can preserve our gravel resources and consume less raw materials.

- Additionally, using recycled concrete means needing less transportation.

- By using recycled concrete, you can reduce fuel consumption.

- By using a portable crusher, crushing can take place on-site.

- Reuse the material as filling material, as one example. There will also be no costs for dumping.

Using recycled concrete and asphalt is not only good for the environment, but it is also less costly than having to dispose of the materials in a landfill.

Reach out to our office today at 301-669-6700 to find out more about our onsite recycled concrete crushing or hauling services.